SiC sealing rings Deep cavity wire drawing dies 3 inch wafer for acoustic devices

Due to the extraordinary high concentration of atomic hydrogen resulted from the very high temperatures generated by the arc discharge, diamond thin films by DC Arc Plasma Jet usually have a higher thermal conductivity, and a better crystal quality (as shown by Raman) , even at relatively high growth rate. Apparently this is beneficial for applications in the field of cutting tools and friction and wear. Particularly, high growth rate easily achievable by DC Arc Plasma Jet may suppress (delay) the outward diffusion of cobalt in the cemented carbide, which will promote the adhesion of the diamond film coatings on the surface of the cemented carbide tools. Besides, higher crystal quality and higher thermal conductivity are also beneficial for acoustic applications.

Applications

Diamond thin film

coated SiC for sealing applications in a harsh environment.

Diamond thin film coated

deep-cavity cemented carbide wire drawing dies (with circular cross section

cavities).

Diamond thin film

coated deep-cavity cemented carbide wire drawing dies (with irregular shaped

cavities)

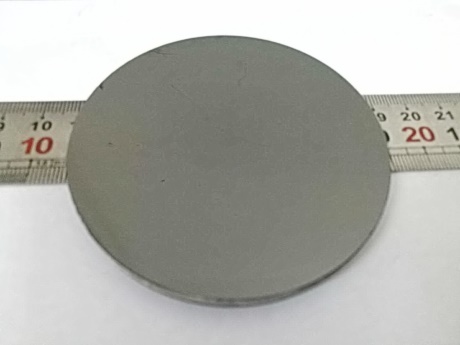

Diamond thin film coated silicon

wafer for acoustic applications (high frequency (GHz) surface acoustic wave

(SAW) devices).

Diamond thin film

coatings for the application field of friction and wear.

Advantages

Low friction coefficient;

Excellent wear resistance;

Excellent thermal stability;

Good uniformity;

Good adhesion。

Specifications

Vickers hardness: 8000-10000mm2

Young's Modulus: 1000-1100GPa

Friction Coefficient: 0.05-0.1

Thickness: <50μm

Thickness after polishing: <30 μm

Qr code

Qr code