One of the remarkable properties of diamond is its unsurpassed thermal conductivity, which is

five times higher than that of copper. As we all know, heat is conducted by electrons in metal, however, lattice vibrations are the key factor for the high thermal conductivity of diamond.

Due to the extraordinary high concentration of

atomic hydrogen produced by the very high temperatures of the arc discharging,

diamond films with high thermal conductivity can be easily obtained even at

relatively high growth rate by DC Arc Plasma Jet. The thermal conductivity of

our optical quality CVD diamond made by our company through DC Arc Plasma Jet approaches

that of the natural type IIa diamond, 2000W/mK. Thermal conductivity can be

tailored within the range of 800-2000 W/mK, and thus can be subdivided in to

different quality grades to meet the different needs of our customers in

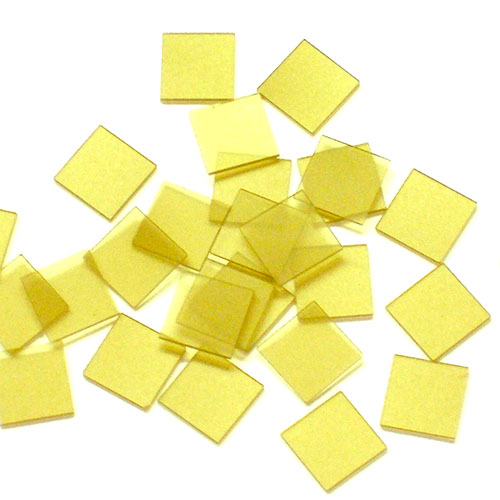

different application fields. At present, CVD diamond made by our company is

used as mounts for high-power integrated circuits, laser diodes, GaN on Diamond

(GOD) and heat spreaders for satellite based electronic systems.

Specifications

Thermal Grade:

Thermal conductivity level:

Standard Medium: >1200W/m.k

High: >1500W/m.k

Excellent:>1800W/m.k (up to

2000W/m.k)

Flatness: <4um/cm

Density: 3.5g/cm3

Young's modulus: 1000-1100GPa

Growth side surface finish: <100 nm Ra

Nucleation side surface finish: <30 nm Ra

Standard Sizes

Double sides polished : Up to diameter 150 mm

As grown thickness: Between 0.3 mm and 1.5 mm

Polished thickness: Between 0.2 mm and 1.0 mm

Qr code

Qr code